Top 6 Best Epoxy for Woodworking

Woodworking projects often require strong, durable adhesives. Epoxy is a top choice for many woodworkers.

It provides excellent bonding and a smooth finish. Are you looking to find the best epoxy for your woodworking projects? You are in the right place. With so many options available, it can be challenging to choose the right one.

This blog will guide you through the top six best epoxies for woodworking. We will explore each option’s features and benefits, ensuring you make an informed decision. Whether you are a beginner or a seasoned woodworker, finding the right epoxy is crucial. Let’s dive in and discover the best epoxy products that can elevate your woodworking projects.

Introduction To Epoxy For Woodworking

Epoxy has become a popular material in woodworking for its versatility and strength. Woodworkers use epoxy to fill gaps, create a glossy finish, or bond pieces together. Understanding epoxy’s benefits can enhance your woodworking projects. In this section, we will explore what epoxy is and its benefits in woodworking.

What Is Epoxy?

Epoxy is a type of adhesive made from resin and hardener. When mixed, these components form a strong, durable bond. This bond is resistant to heat, chemicals, and moisture. Epoxy is available in different types, including clear and colored options. Each type serves specific purposes in woodworking projects.

Benefits Of Using Epoxy In Woodworking

Epoxy offers several benefits for woodworking projects. It creates a strong bond that holds wood pieces together securely. This bond is resistant to environmental factors like heat and moisture.

Epoxy also fills gaps and cracks in wood. This improves the appearance and strength of the finished project. Woodworkers use epoxy to create smooth, glossy finishes. These finishes enhance the wood’s natural beauty and protect it from damage.

Additionally, epoxy is versatile and easy to use. You can mix it with pigments to achieve different colors. This allows for creative and unique designs in your woodworking projects.

Factors To Consider When Choosing Epoxy

Choosing the right epoxy for woodworking projects can be challenging. There are several factors to consider to ensure you select the best product for your needs. Below are some key considerations to help you make an informed decision.

Curing Time

Curing time is critical in epoxy selection. Some epoxies cure quickly, others take longer. Fast-curing epoxies are ideal for small projects. Slow-curing options work best for larger projects. Knowing your project’s timeline helps you pick the right curing time.

Viscosity

Viscosity affects how the epoxy spreads and penetrates the wood. Low-viscosity epoxies flow easily and fill small gaps. High-viscosity options are thicker, perfect for vertical surfaces. Choose according to your project’s needs.

Durability

Durability is a key factor in epoxy selection. The epoxy should withstand wear and tear. Some epoxies offer UV resistance and water resistance. Ensure the epoxy you choose matches the environment it will be used in.

Safety

Safety is paramount when working with epoxy. Some epoxies contain harmful chemicals. Look for non-toxic, low-VOC options. Always use protective gear and work in a well-ventilated area. Ensure you follow all safety guidelines provided by the manufacturer.

Best Epoxy For Woodworking Projects

Woodworking projects often require durable and reliable adhesives. Epoxy is the top choice for many woodworkers. It offers strength, clarity, and a smooth finish. Let’s explore the best epoxy options for your woodworking projects.

Clear Cast Epoxy Resin is perfect for creating a glossy finish. It is clear and transparent, enhancing the wood’s natural beauty. Ideal for coating surfaces or filling small voids, it ensures a smooth and polished look.

Marine Grade Epoxy is known for its water resistance. This makes it suitable for outdoor furniture and boat repairs. It provides a strong bond, even under harsh conditions. Perfect for projects exposed to moisture.

Tabletop Epoxy is designed for surfaces like countertops and tables. It offers a high-gloss finish that is both durable and attractive. This epoxy is easy to apply and self-leveling, creating a smooth surface.

Deep Pour Epoxy is ideal for thick pours and river tables. It allows for pours up to 2 inches thick without overheating. This epoxy cures slowly, reducing the risk of bubbles. Perfect for deep casting projects.

Fast Cure Epoxy is great for projects that need a quick turnaround. It sets rapidly, allowing you to work faster. This epoxy is strong and reliable, making it suitable for repairs and small projects.

UV Resistant Epoxy prevents yellowing caused by sunlight exposure. It maintains its clarity and gloss over time. Ideal for outdoor projects, it ensures long-lasting beauty and durability.

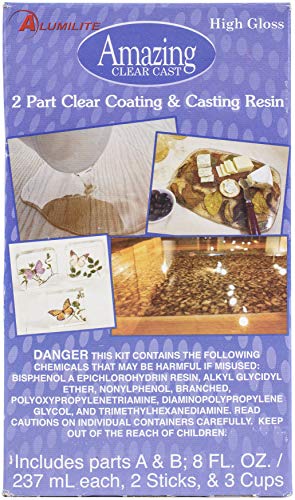

Clear Cast Epoxy Resin

Clear Cast Epoxy Resin offers a smooth, glossy finish perfect for woodworking projects. Ideal for creating durable, crystal-clear surfaces on wood.

- ADDED UV RESISTANCE: Nothing can stop clear resins from yellowing over time. But we’ve been able to slow down the yellow…

- EASY-TO-USE FORMULA: This crystal clear epoxy resin has a 1:1 ratio by volume that’s easy to follow, so both beginners a…

- LIMITLESS COLOR CUSTOMIZATION: Design your basic tumbler using decorative vinyl decals, glitter, or a pop of color to su…

Clear Cast Epoxy Resin is a popular choice among woodworking enthusiasts. This resin provides a crystal-clear finish that enhances the natural beauty of wood. It also offers exceptional durability, making it a reliable option for various woodworking projects.

Features

Clear Cast Epoxy Resin is known for its high-gloss finish. It is UV-resistant, which helps prevent yellowing over time. The resin also cures to a hard, durable surface that resists scratches and water. Additionally, it has a low odor during application, which makes it easier to work with.

Ideal Uses

This epoxy resin works well for coating wooden countertops. It is also suitable for making jewelry and other decorative items. Clear Cast Epoxy Resin can be used for sealing wooden surfaces, enhancing their appearance and longevity.

Pros And Cons

One of the main advantages of Clear Cast Epoxy Resin is its clear, glossy finish. It is also durable and UV-resistant, which prevents yellowing. The low odor during application is another benefit. However, it requires precise mixing and application to achieve the best results. It can also be more expensive compared to other types of epoxy.

Marine Grade Epoxy

Marine Grade Epoxy is a high-strength adhesive known for its durability and water resistance. It is widely used in woodworking projects that require strong bonding and protection from moisture. This epoxy is perfect for outdoor furniture, boats, and other items exposed to harsh weather conditions.

- Two-part epoxy cold weld system specially formulated for marine applications

- Great for bonding aluminum, metal, composites, fiberglass and more

- Sets in 4-6 hours at room temperature and cures dark grey in 15-24 hours

Features

- Waterproof: Marine Grade Epoxy provides excellent water resistance.

- Strong Bonding: It creates a durable bond that withstands stress.

- UV Resistant: This epoxy resists UV damage, preventing yellowing.

- Versatile: Suitable for various woodworking projects.

Ideal Uses

Marine Grade Epoxy is ideal for:

- Building and repairing boats.

- Outdoor furniture projects.

- Wooden decks and docks.

- Waterproofing wooden surfaces.

- Creating durable wood joints.

Pros And Cons

| Pros | Cons |

|---|---|

| Highly durable and water-resistant. | Long curing time. |

| Resistant to UV rays. | Can be expensive. |

| Strong adhesion on various surfaces. | Requires proper ventilation during use. |

Tabletop Epoxy

Tabletop epoxy is a popular choice for woodworking projects. It provides a clear, glossy finish that enhances the beauty of wood. This type of epoxy is known for its durability and resistance to scratches and heat. Whether you’re creating a new table or refinishing an old one, tabletop epoxy can provide a professional look.

- Crystal Clear Epoxy Resin: LET’S RESIN epoxy resin delivers a flawless, crystal clear finish that’s perfect for all DIY …

- Bubble-Free Clear Resin: Our clear casting resin is as pristine as glass, ensuring a bubble-free result that’s ideal for…

- Mold-Friendly and Fast Cure: LET’S RESIN clear resin kit is designed to be friendly to silicone molds, with controlled h…

Features

Tabletop epoxy offers several key features. It is self-leveling, ensuring a smooth surface. It is UV resistant, which helps prevent yellowing over time. This epoxy has a long working time, allowing you to correct mistakes. It is also water-resistant, making it suitable for various environments.

Ideal Uses

Tabletop epoxy is ideal for many woodworking projects. It is perfect for creating custom tabletops. You can use it to coat countertops. It works well for bar tops. This epoxy is great for art projects. It is also useful for coating wooden furniture.

Pros And Cons

Using tabletop epoxy has several pros. It provides a clear, high-gloss finish. It is durable and scratch-resistant. This epoxy is easy to apply. It has a long working time. It is also UV resistant.

There are some cons to consider. It can be expensive. It requires careful application to avoid bubbles. It may need multiple coats for a perfect finish. It also has a strong odor during application.

Deep Pour Epoxy

Deep pour epoxy is a game-changer for woodworking projects. It’s designed for thick, clear pours, making it perfect for river tables and large castings. The ability to pour deep layers without bubbles or imperfections sets it apart from other epoxies.

- TRUE DEEP POUR: Experience the ease of 2-4 inch pours with our advanced Liquid Glass Deep Pour Epoxy. Perfect for river …

- UNMATCHED DURABILITY: Crafted to endure, Superclear 2.0 sets the standard for strength. Its rock-hard curing provides ex…

- BUBBLE-LESS TECHNOLOGY: Say goodbye to imperfections with our low viscosity Liquid Glass Epoxy. Its unique formulation a…

Features

Deep pour epoxy offers a long working time. It cures slowly, which helps reduce bubbles and cracks. This epoxy is UV-resistant, maintaining clarity over time. It’s also self-leveling, ensuring a smooth, even surface.

Ideal Uses

Deep pour epoxy is ideal for river tables. It’s perfect for filling large voids in wood slabs. Use it to create stunning, clear castings and embeds. This epoxy works well for large-scale art projects, too.

Pros And Cons

Pros:

- Long working time

- Reduces bubbles

- UV-resistant

- Self-leveling

Cons:

- Long curing time

- Requires precise mixing

- Can be expensive

Fast Cure Epoxy

Epoxy adhesives are essential in woodworking for their strength and durability. One type gaining popularity is the Fast Cure Epoxy. This epoxy offers quick curing times, making it perfect for projects needing fast results. Let’s explore its features, ideal uses, and pros and cons.

- Dries clear: Our Gorilla Tough epoxy resin dries clear for a clean finish and incredibly durable hold; perfect for house…

- 5 minute epoxy: This epoxy resin kit in just one applicator has a 5 minute set time, plenty for repositioning and adjust…

- Gap filling: Gorilla resin epoxy also acts as a gap filler, filling voids and bonding uneven or vertical surfaces

Features

The Fast Cure Epoxy has several notable features:

- Quick Setting Time: Cures within 5 to 30 minutes.

- High Bond Strength: Provides a durable and strong bond.

- Clear Finish: Dries clear for a clean look.

- Water Resistant: Suitable for both indoor and outdoor projects.

Ideal Uses

This epoxy is versatile and can be used for various woodworking projects:

- Repairing furniture

- Creating small wooden crafts

- Bonding wood to other materials

- Filling gaps in wooden surfaces

Pros And Cons

Understanding the pros and cons can help determine if Fast Cure Epoxy is right for your project:

| Pros | Cons |

|---|---|

| Quick curing time | Shorter working time |

| High bond strength | May be more expensive |

| Clear finish | Requires precise mixing |

| Water resistant | Limited shelf life |

Uv Resistant Epoxy

When working with wood, UV resistant epoxy is a must-have. It protects your projects from sun damage. This type of epoxy ensures your woodwork remains beautiful and durable.

- 【300g PREMIUM UV EPOXY RESIN】 You will get the uv epoxy resin with the following characteristics: crystal clear, super h…

- 【HEALTHY and SAFE】 You can rest assured to use our UV resin with Safety Data Sheet. The ingredients of YIEHO UV RESIN ha…

- 【SUPER CLEAR and HARD TYPE UV CURE RESIN 300g】The UV epoxy resin uses advanced materials such as Bisphenol A Epoxy Acryl…

Features

UV resistant epoxy has unique features. It offers excellent UV protection. This helps prevent yellowing and degradation. It is also clear and glossy. This enhances the natural beauty of wood. The epoxy is durable and long-lasting. It ensures your projects withstand harsh conditions. It is also easy to apply. Perfect for both beginners and professionals.

Ideal Uses

UV resistant epoxy is ideal for outdoor furniture. It protects against sun exposure. It is perfect for boat building. Keeps the wood safe from UV rays. Suitable for countertops. Adds a protective and glossy finish. Great for artistic projects. Enhances the beauty of wooden sculptures and carvings.

Pros And Cons

Pros:

- Excellent UV protection

- Prevents yellowing

- Clear and glossy finish

- Durable and long-lasting

- Easy to apply

Cons:

- Can be expensive

- Requires proper ventilation during application

- May need multiple coats for best results

Tips For Using Epoxy In Woodworking

Discover the top 6 best epoxy for woodworking projects. Find tips on choosing the right epoxy and ensure a strong bond. Perfect for creating durable and beautiful wood pieces.

Epoxy is a versatile material for woodworking projects. It can fill gaps, seal surfaces, and create a glossy finish. To achieve the best results, follow these tips for using epoxy in woodworking.

Proper Mixing Techniques

Mixing epoxy correctly is crucial for its performance. Follow these steps to ensure a proper mix:

- Use a clean container for mixing.

- Measure the epoxy resin and hardener accurately.

- Mix the components thoroughly for at least 3 minutes.

- Scrape the sides and bottom of the container while mixing.

- Avoid bubbles by mixing slowly and steadily.

Application Tips

Applying epoxy requires careful attention to detail. Here are some tips to help you:

- Prepare the wood surface by sanding and cleaning it.

- Use a brush or roller to apply the epoxy evenly.

- Apply thin layers to avoid drips and runs.

- Allow each layer to cure before adding another.

- Sand between layers for a smooth finish.

Safety Precautions

Safety is important when working with epoxy. Follow these precautions:

- Wear gloves to protect your skin.

- Use a mask to avoid inhaling fumes.

- Work in a well-ventilated area.

- Keep epoxy away from open flames.

- Clean up spills immediately with appropriate solvents.

By following these tips, you can achieve professional results with epoxy in your woodworking projects.

Conclusion

Choosing the right epoxy is crucial for successful woodworking projects. The top six options we’ve discussed offer great bonding and durability. Each has unique features suited for different needs. Remember to consider your project’s requirements before selecting. Quality epoxy ensures strong and lasting results.

Happy woodworking!